New/updated @ eXtension

Undercover Nutrient Investigation: The Effects of Mulch on Nutrients for Blueberry Webinar

Watch the webinar on YouTube at https://www.youtube.com/watch?v=A9l5qhyg-04

About the webinar

Learn about ongoing research from Oregon State University's Organic Blueberry Project. Research team members Dr. Dan Sullivan, Ryan Costello, and Luis Valenzuela of Oregon State University will discuss nutrient monitoring techniques used to measure mulch effects on nutrient availability, salts, and pH. Small scale methods for compost recipe development for blueberry will also be highlighted.

About eOrganic

eOrganic is the Organic Agriculture Community of Practice at eXtension.org. Our website at http:www.extension.org/organic_production contains articles, videos, and webinars for farmers, ranchers, agricultural professionals, certifiers, researchers and educators seeking reliable information on organic agriculture, published research results, farmer experiences, and certification. The content is collaboratively authored and reviewed by our community of University researchers and Extension personnel, agricultural professionals, farmers, and certifiers with experience and expertise in organic agriculture.

This is an eOrganic article and was reviewed for compliance with National Organic Program regulations by members of the eOrganic community. Always check with your organic certification agency before adopting new practices or using new materials. For more information, refer to eOrganic's articles on organic certification.

eOrganic 4935

ABCs of Organic Certification Webinar

Watch the video on YouTube at https://www.youtube.com/watch?v=ZiYAsSDrgB4

About the webinar

Thinking about getting certified, but don't know where to start? Have questions about the USDA organic standards? Join national organic expert, Jim Riddle, University of Minnesota, as he explains the National Organic Program crop production requirements and certification process. Good for growers, Extension agents, ag professionals, and organic food eaters.

About Jim Riddle

Jim Riddle has worked for over 26 years as an organic farmer, inspector, author, policy analyst and educator. He was founding chair of the International Organic Inspectors Association, (IOIA), and co-author of the IFOAM/IOIA International Organic Inspection Manual. He has trained hundreds of organic inspectors throughout the world. Jim served on the Minnesota Department of Agriculture’s Organic Advisory Task Force from 1991-2009, and was instrumental in passage of Minnesota’s landmark organic certification cost-share program. Since January 2006, Jim has worked as the University of Minnesota’s Organic Outreach Coordinator. Jim is former chair of the USDA’s National Organic Standards Board, and is a leading voice for organic agriculture.

About eOrganic

eOrganic is the Organic Agriculture Community of Practice at eXtension.org. Our website at http:www.extension.org/organic_production contains articles, videos, and webinars for farmers, ranchers, agricultural professionals, certifiers, researchers and educators seeking reliable information on organic agriculture, published research results, farmer experiences, and certification. The content is collaboratively authored and reviewed by our community of University researchers and Extension personnel, agricultural professionals, farmers, and certifiers with experience and expertise in organic agriculture.

This is an eOrganic article and was reviewed for compliance with National Organic Program regulations by members of the eOrganic community. Always check with your organic certification agency before adopting new practices or using new materials. For more information, refer to eOrganic's articles on organic certification.

eOrganic 4876

Organic Farming Financial Benchmarks Webinar by eOrganic

Watch the video on YouTube at https://www.youtube.com/watch?v=CC7h1nA-fUY

Resources from the Webinar

- FINBIN: http://www.finbin.umn.edu/

- Center for Farm Financial Management: http://www.cffm.umn.edu/

About the webinar

While there is much anecdotal information about farm performance and profitability, real world information about production, financial performance, and profitability on organic farms is scarce.

Since 2006, researchers at the University of Minnesota’s Center for Farm Financial Management and their partners have been collecting and analyzing farm financial data on organic farms and integrating them into FINBIN, one of the largest and most accessible sources of farm financial and production benchmark information in the world. Through their work, they are documenting the financial performance of participating organic producers so that they and their peers have more accurate benchmarks on which to evaluate organic options, as well as to un-mask the financial performance of a group of organic producers to provide agricultural lenders better information on which to base credit decisions and to give policy makers, researchers, and others real-world insight into organic farm performance.

In this webinar, Dale Nordquist, Center for Farm Financial Management at the University of Minnesota, will describe the Minnesota Organic Farm Business Management Project, and show three years worth of results of organic farm financial performance in Minnesota.

About eOrganic

eOrganic is the Organic Agriculture Community of Practice at eXtension.org. Our website at http:www.extension.org/organic_production contains articles, videos, and webinars for farmers, ranchers, agricultural professionals, certifiers, researchers and educators seeking reliable information on organic agriculture, published research results, farmer experiences, and certification. The content is collaboratively authored and reviewed by our community of University researchers and Extension personnel, agricultural professionals, farmers, and certifiers with experience and expertise in organic agriculture.

This is an eOrganic article and was reviewed for compliance with National Organic Program regulations by members of the eOrganic community. Always check with your organic certification agency before adopting new practices or using new materials. For more information, refer to eOrganic's articles on organic certification.

eOrganic 4855

Organic Late Blight Management 2009 Webinar by eOrganic

Watch the video on YouTube at https://www.youtube.com/watch?v=21-3WwRYiME

Late blight is a serious disease of potato and tomato family (Solanaceous) crops worldwide that can be difficult to control organically. eOrganic presenters Dr. Sally Miller of Ohio State University, Dr. Meg McGrath of Cornell University, and Dr. Alex Stone of Oregon State University discussed the 2009 epidemic and how to diagnose, prevent, and manage late blight on organic farms.

For additional webinars on late blight presented in 2010, see:

Late Blight Management on Organic Farms: 2010 Webinar

Late Blight Control in Your Organic Garden: 2010

This is an eOrganic article and was reviewed for compliance with National Organic Program regulations by members of the eOrganic community. Always check with your organic certification agency before adopting new practices or using new materials. For more information, refer to eOrganic's articles on organic certification.

eOrganic 4868

Pollination and Fertilization in Organic Seed Production

eOrganic authors:

John Navazio, Organic Seed Alliance and Washington State University

Frank Morton, Wild Garden Seed

Micaela Colley, Organic Seed Alliance

Linda Brewer, Oregon State University

Alex Stone, Oregon State University

This is an Organic Seed Resource Guide article.

Understanding the Reproductive Cycle of Seed CropsThere are several key reproductive steps in the life cycle of a flowering plant that results in adequate seed set. Pollination and subsequent fertilization of the ovules in the fruit are crucial processes in producing viable seed. There are a number of environmental challenges that can disrupt these processes and result in poor quality and quantity of a seed crop. Learning the basic steps of the reproductive process is very important in learning how to improve both the quality and quantity of the seed that you produce.

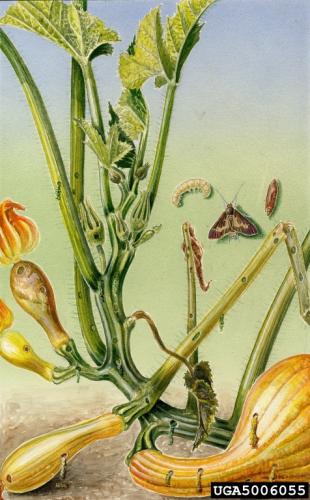

Squash flower pollination. Photo credit: Micaela Colley, Organic Seed Alliance.

Pollination, the movement of pollen from the anthers to the stigma, is essential for seed set and therefore crucial in seed production. An important consideration for any seed grower to know is whether the seed crop species that they are producing is predominately self-pollinated or cross-pollinated. Self–pollinated species have evolved to have perfect flowers that remain closed throughout the pollination process. These perfect flowers (bearing both male and female sexual parts on each flower) have anthers which are borne close to the stigma, allowing easy transfer of pollen to the stigmatic surface. This short journey for pollen to move from anther to stigma of the same flower (thus self-pollinating) often requires some external movement like wind to stimulate good pollen coverage of the stigma. In some selfers (runner beans and favas are good examples) insect visitation, even when the insect is unable to open the flower, can substantially increase seed set through their movement. Any grower producing a tomato crop in the greenhouse knows that the plants need a physical shaking or stiff air flow in order to achieve optimum pollination and subsequent fruit set on their crop.

Cross-pollinated species require genetic mixing between individuals of a population in order to remain genetically sound. All cross-pollinated crop species rely on either wind or insects (and occasionally animals) for pollen movement between individuals. All cross-pollinated crop species have flowers that open before pollen shed and receptivity. It is crucial that all of these species have adequate pollen availability during the flowering period. This requires; 1) a large enough population of the crop flowering in unison, 2) adequate insect populations present and visiting the crop or wind/airflow that is sufficient to move enough pollen for optimum pollination, and 3) environmental conditions that are such that pollen remains viable from the time of pollen shed until it reaches the flowers of other individuals in the population.

Fertilization and Seed FormationThe next step in this process leads to the fertilization of the ovules which become the seeds. After the pollen lands on the stigma, the receptive tip of the female parts of the flower, it must germinate and form a pollen tube which grows down through the style to reach the ovary. Each pollen tube that successfully reaches the ovary delivers one male gamete to fertilize an egg cell and one to fertilize the polar nuclei in a single ovule resulting in the formation of one seed. This fertilization event requires favorable environmental conditions and for fruit with multiple ovules a number of independent fertilization events must occur to insure good seed set. Once the embryo and endosperm form as a result of fertilization the seed undergoes a period of rapid cell division and growth. In most seed crops this growth and maturation of seed occurs in 40 to 60 days.

Problems in PollinationUpon release of the pollen from the anthers, the environmental conditions must be such that the pollen grain remains viable until it reaches the stigma of a flower of the same species. If it is too hot, the pollen may be denatured; if it is too dry, the pollen may desiccate and lose viability before reaching a receptive stigma. If it is too cool or rainy, the activity of pollinating insects can be reduced; honey bees are especially sensitive to these conditions and will not fly when it is too cool or wet. Rainy conditions can also impede the movement of pollen in wind-pollinated species as it can wet the pollen as anthers open and wash much of the pollen to the ground or make it immobile in wind pollinated species.

Another condition that can impede pollination for all self-pollinated species or wind-pollinated cross-pollinated species is to have little or no airflow at the time of pollen maturation and release. In self-pollinating plants, the anthers are always borne in close proximity to the stigma within the closed flowers common to all selfers. In some cases it is so close that just the act of dehiscence (the opening of the anther to release the pollen) will cause the pollen to fall onto the stigma with little or no prompting. However, in many cases this short journey requires some type of external movement to literally shake the pollen from the anthers onto the stigma. In many selfing species (tomatoes, peppers, common bean, peas) this is easily accomplished when the plant is grown outdoors by the movement of the plant in the wind. In some selfers (runner beans and favas are good examples) insect visitation, even when the insect is unable to open the flower, can substantially increase seed set through their movement. Any grower producing a tomato crop in the greenhouse knows that the plants need a physical shaking or stiff air flow in order to achieve optimum pollination and subsequent fruit set on their crop. When wind-pollinated crossers like corn, spinach, or beets are grown in the absence of normal wind and airflow during flowering, several days of unusually still air can hinder full seed set (or random mating across the population for the genetic mixing that is essential for crossers) due to low pollen flow in the air.

Problems in FertilizationFrom the time that the pollen comes in contact with the stigma, there are a number of problems that can arise. If the ambient temperatures are too high the pollen can become denatured and if it’s too low then the pollen will just sit until the temperature rises, although the flower’s receptivity is short lived. If the relative humidity is too low at this stage then the stigma or the pollen can desiccate, preventing the germination of the pollen. Low relative humidity has been found to be the culprit in a poor seed set for these reasons in a number of instances in vegetable seed production in the arid western states. The next step in the process of fertilization, the pollen tube growing down through the style can also be derailed by unfavorable weather conditions. The pollen tube is essentially a free living miniature plant (the gametophyte generation) and requires temperatures similar to the mother plant to grow vigorously. The pollen tube’s life cycle is usually 24 hours or less and it must make the trip from stigma to ovule in this period or not be successful in fertilizing the ovule. If the ambient temperature during this short period of time is colder or hotter than temperatures favorable to normal growth of the species than the pollen tube will stop growing and fail restart when the temperature comes back into a favorable range for growth. This will result in no fertilization for that particular pollen tube. In a cool loving crop like spinach that produces luxuriant growth at 58 – 65F (15 – 18C) and virtually stops growth at 78F (25.5C), this means that when it gets hotter than 78F (25.5C) as spinach seed crops are flowering there can be serious damage done to the yield due to poor fertilization of the ovules. Alternately, a heat loving crop like tomatoes can suffer blossom drop producing fewer fruit with low seed yields when tomatoes are exposed to cold night time temperatures during flowering.

Figure 1. Pollinating mechanisms and systems in common vegetable crops.

Crop Species

Primary Pollinating Mechanism(s)

Pollinating system

Wild Crossable Species in US

Self #1: self pollinating species, outcrossing is usually < 1%

Self #2: self-pollinating species that often outcross between 2-5%

Self #3: self-pollinating species that may cross at rates > 5%

Web Resources

- Bees and pollination [Online]. C. Britton. Ohio Agriculture Research and Development Center. The Ohio State University. Available at: http://osu.campusguides.com/agnic_bees_pollination (verified 11 June 2015).

- Evaluating honey bee colonies for pollination: a guide for growers and beekeepers [Online]. M. Burgett. 1984. Pacific Northwest Extension Publication 245. Available at: http://ir.library.oregonstate.edu/xmlui/handle/1957/16802 (verified 1 April 2011).

- Pollination [Online]. Honeybee Program and Entomology Department. University of Georgia. Available at: http://www.caes.uga.edu/departments/ent/bees/pollination/background.html (verified 1 April 2011).

- Insect pollination of cultivated crop plants [Online]. S.E. McGregor. Originally published in 1976. USDA Handbook 496. The first and only continuously updated virtual beekeeping book. Available at: https://www.ars.usda.gov/ARSUserFiles/20220500/OnlinePollinationHandbook.pdf (verified 14 June 2019).

- The Pollination Home Page [Online]. Pollination information and images. Includes state-by-state listings of beekeepers with bees available for contract pollination. Available at: http://pollinator.com/ (verified 1 April 2011).

- The Xerces Society Pollinator Conservation Program [Online]. Contains excellent downloadable or print information on how to provide habitat for native pollinators on your farm. Available at: http://www.xerces.org/pollinator-conservation/ (verified 1 April 2011).

- Farming for bees: guidelines for providing native bee habitat on farms [Online]. M. Vaughan, M. Shepherd, C. Kremen and S. H. Black. 2007. Available at: http://www.xerces.org/guidelines-farming-for-bees/ (verified 1 April 2011).

- Pacific Northwest plants for native bees [Online]. M. Shepherd. Undated. Available at: http://www.xerces.org/wp-content/uploads/2008/11/pnw_plants_bees_xerces_... (verified 1 April 2011).

- California plants for native bees [Online]. M. Shepherd. Undated. Available at: http://www.xerces.org/wp-content/uploads/2008/11/california_plants_for_n... (verified 1 April 2011).

- Using farm bill programs for pollinator conservation (draft) [Online]. M. Vaughn and M. Skinner. 2008. Available at: http://www.xerces.org/wp-content/uploads/2008/11/using_farm_bill_program... (verified 1 April 2011).

- Xerces Society fact sheets on native bee pollination of specific agricultural crops:

- Native bee pollination of watermelon [Online]. C. Kremen, N. Williams, S. Greenleaf, and R. Thorp. Undated. Available at: http://www.xerces.org/wp-content/uploads/2008/10/factsheet_watermelon_po... (verified 1 April 2011).

- Native bee pollination of cherry tomatoes [Online]. C. Kremen, N. Williams, S. Greenleaf, and R. Thorp. Undated. Available at: http://www.xerces.org/wp-content/uploads/2008/10/factsheet_cherry_tomato... (verified 1 April 2011).

- Native bee pollination of hybrid sunflowers [Online]. C. Kremen, N. Williams, S. Greenleaf, and R. Thorp. Undated. Available at: http://www.xerces.org/wp-content/uploads/2008/10/factsheet_sunflower_pol... (verified 1 April 2011).

- Crop pollination by bees. K.S. Delaplane and D.F. Mayer. 2000. CABI Press, New York, NY.

- Insect pollination of crops. J.B. Free. 1993. Academic Press, London, UK, and San Diego, CA.

- Pollinator conservation handbook. 2003. The Xerces Society. Portland, OR.

This is an eOrganic article and was reviewed for compliance with National Organic Program regulations by members of the eOrganic community. Always check with your organic certification agency before adopting new practices or using new materials. For more information, refer to eOrganic's articles on organic certification.

eOrganic 422

Organic Certification and Soil Conservation Compliance

eOrganic authors:

Michelle Wander, University of Illinois

Susan Andrews, USDA - Natural Resource Conservation Service

This article reviews the conservation goals for organic farming systems and considers how well organic certification standards line up with the Natural Resources Conservation Services's programs (EQIP, transition payments) and objectives. It provides research results from an Integrated Organic Program study evaluating organic transiton strategies and compares measured trends in soil organic matter with ranks produced by NRCS tools (soil conditioning index and soil and water eligibility tools) developed to estimate conservation outcomes. It introduces the new Conservation Management tool that will be used to implement the Conservation Stewardship Program.

Introduction: Goals and Approach of Organic Standards and NRCS Programs

Implementation Varies by State

Organic Concerns About NRCS Enrollment Tools

Tool Performance in the Windsor Organic Research Trial

Additional Resources

References and Citations

The National Organic Program (NOP) and the Natural Resource Conservation Service (NRCS) share the goal of natural resource protection. The NOP defines organic production as “production system that is managed in accordance with the Act and regulations in this part to respond to site-specific conditions by integrating cultural, biological, and mechanical practices that foster cycling of resources, promote ecological balance, and conserve biodiversity.” Promotion of ecological balance and conservation of biodiversity are defining principles of organic agriculture. The NOP requires that organic producers must maintain or improve the natural resources of the operation, including soil and water quality, and minimize soil erosion. Organic growers comply with these requirements by implementing conservation practices, such as crop rotations, cover crops, grass waterways, and contour strips. Many also grow annual and perennial flowering plants (farmscaping) to provide food and habitat for pollinators, natural enemies of insect pests, and other beneficial organisms. Some also erect bird and bat houses to enhance biodiversity and improve pest control.

The NRCS is a Federal agency that pursues natural resource protection goals through the delivery of technical assistance to land owners and attempts to tailor this information to address client needs. The institution administers federal conservation programs that provide cost share and technical assistance for conservation implementation, and, in some cases, financial incentives. Participation in NRCS programs is voluntary and only people managing private lands are eligible. Resource concerns of the agency include: soil quality, water quantity and quality, air quality, production animal and wildlife management, and plant health and suitability. The NRCS maintains the Organic Initiative Practice List and National Organic Program Rules Matrix (PDF; 52KB) which correlates the organic system plan and organic certification requirements with NRCS conservation practices. (Not all practices are appropriate in all areas.) It provides guidance on land management practices as varied as Aquaculture Ponds, Channel Stabilization, Pest Management, Residue and Tillage Management, Conservation Rotation, and Cover Crops for croplands, forests, and pastures. The NRCS standards and practice criteria are fully compatible with organic farming systems and can be readily applied to, and adopted on, organic farms. National practice standards are reviewed and updated every five years (or sooner, if warranted by technology change).

Both the NOP and NRCS approaches appreciate the site-specific nature of farming and conservation concerns. NRCS programs vary across the country because state offices are asked to modify national standards to make them more applicable to their local conditions. States may also propose new standards, introduced as interim standards, that upon review may become national standards after three years. Job Sheets and Technical Notes provide specifics about how to implement practice standards.

USDA provides information about relevant practices and resources specifically for organic systems.

Implementation Varies by State

The NRCS programs and National Organic Program regulations both assess management practices, such as rotation, fertilizer additions, and tillage, as a way to evaluate stewardship. In some cases, NRCS uses producer records of practices to run models or evaluation tools that predict outcomes such as erosion, changes in organic matter, water quality, and biodiversity. Self-reporting of practices, with later field visits for verification, is also used. Organic farmers also depend on self-reporting of practices in the form of a farm management plan, called the Organic System Plan (OSP), that is a required part of their certification document. As a part of this document, organic farmers describe the practices they use to prevent runoff, manage water movement onto their farm, and prevent nutrients from leaving the farm. In addition, organic farmers are required to monitor their practices to demonstrate compliance, and maintain records of all inputs, activities, and transactions; these are examined at least annually during the certification inspection. For more on organic certification documents, see Organic Certification of Vegetable Operations.

The retains and expands several areas of support for organic. This includes support provide through the Environmental Quality Incentives Program (EQIP) in the form of payments and technical assistance for conservation practices, and for transitioning an operation to organic production, and through cost share

Organic Concerns About NRCS Enrollment ToolsThe Conservation Security Program (CSP) was first introduced in the 2002 Farm Bill. Working lands provisions provided an opportunity to reward land managers already implementing conservation practices with "green payments". The initial roll out of the CSP program caused some concern by organic farming groups that felt the program was biased against organic growers because the initial enrollment tool, called the Soil Conditioning Index (SCI), tracked tillage disturbance as a primary factor in reducing soil quality. Many producers who farm organically or live in the warmer climates have had difficulty meeting the minimum criteria for eligibility despite their strong conservation efforts. NRCS has followed up by placing greater emphasis on soil building activities, such a cover crops, mulching, compost additions and by providing expanded training for field agents evaluating practices and giving credit for improving soil biodiversity, which aides nutrient cycling, breaks pest cycles and contributes to increase soil structure, by giving credit for reduced pesticide use and diverse rotations.

Efforts to improve new tools and evaluate performance on organic farms are underway as NRCS works to implement the revised Conservation Stewardship Program contained in the 2008 Farm Bill. The 2008 Farm Bill made many improvements that should be attractive to organic farmers. One key difference is that it seeks to reward producers who have historically used good stewardship practices as well as provide iincentives for those who want to do more. It is no longer watershed based and considers the managment of the farm as a whole, not just individual fields. The new Conservation Stewarship Program will include a crosswalk to help organic and specialty crop producers access the program, as well as outreach and technical assistance to organic and specialty crop producers. It also includes a mandate for NRCS to establish a standard of care for soil, water, and biodiversity that will be predicted based on management practices. NRCS must now establish quality criteria to establish the minimum treatment level necessary to adequately address identified resource concerns for a particular land area. These criteria are described in NRCS’s Field Office Technical Guide. While there are a set of national criteria, each state may add to the criteria to make them more relevant to local conditions.

Tool Performance in the Windsor Organic Research TrialThe NRCS is working to develop and validate tools used to decide which farms—including organic farms—are eligible for program participation. This section reviews some tools that have been used and introduces the new CMT. New tools will build on existing resources including the Soil Conditioning Index (SCI), which evaluates management practices and their influence on soil status. The SCI is currently embedded in RUSLE2 (Revised Universal Soil Loss Equation 2). RUSLE2 a detailed process model that predicts long-term, average-annual erosion by water. The SCI focuses on organic matter and is computed with a weighted function:

SCI = (Organic Matter x 0.4) + (Field Operations x 0.4) + (Erosion x 0.2)

where:

Organic Matter accounts for organic material additions, biomass produced, and decomposition;

Field Operations represents physical disturbance from field operations; and

Erosion is the estimated loss of soil material by sheet, rill, irrigation and/or wind erosion.

When the SCI score is negative, soil organic matter is predicted to be decreasing; for zero or positive SCI scores, soil organic matter is predicted to be stable or increasing. For the history of this tool see Zobeck et al. (2007).

The SCI is estimated for a particular field by running the RUSLE2 model. Users provide information about the soil type and location of the field. Evaluations by NRCS suggest that tool failures often result from problems with model calibration or simple user error. NRCS is working on new expert systems, including the Soil and Water Eligibility Tool (SWET) and products derived from this tool. SWET evaluates management practices based on their contribution to each soil function or water quality concern. The soil properties that SWET scores include organic matter, nutrient cycling, soil habitat, physical stability, and moisture management. The water quality properties SWET scores are sediment, salinity, and surface and groundwater pesticides, nitrogen, and phosphorus. A new conservation compliance tool that is based on SWET is now under development and will be used to determine eligibility for future NRCS programs. Fig. 2 shows the entry screen for this prototype tool. An expert system will be used to determine what practices meet the standards of care established for soil and water resources. Assumptions about practice impacts on soils predict outcomes for soil (organic matter, nutrient cycling, soil physical condition, soil biotic habitat, and soil moisture salinity management) and water quality (leached N, P, and pesticides; sediment loss). Initial validation efforts have compared tool results with measured soil quality data from medium- and long-term research plots (Wienhold et al., 2007; Zobeck et al. 2007).

Figure 2. Screen shot from the SWET tool. The NRCS has already adapted this and incorporated it into a new Conservation Management Tool (CMT).

Table 1 shows the results from an evaluation of NRCS tools (SWET and SCI) and compares them with the soil organic carbon (SOC) concentrations actually measured in the surface soils of replicated research plots in an organic transition experiment in Champaign, IL. Three transitional cropping systems (intensive vegetable, row crop, and perennial pasture or ley), each with three approaches to fertility (crop and cover crop residues only, and residues supplemented with either manure or compost additions), were compared during 2003–2005. For all treatment combinations, the SOC levels increased slightly during the study compared to baseline samples taken at the beginning of transition.

Table 1. Soil quality characterization after three years under different cropping system and soil amendment treatments. SWET2 SCI3 Year 3 SOC Treatment1 Score Eligible? Score Eligible? (%)4 VEG 44 no -0.46 no 2.45 ± 0.72 VEG + manure 52 no 0.86 yes 2.36 ± 0.80 VEG + compost 52 no 2.80 yes 2.39 ± 0.63 ROW 64 yes -0.12 no 2.17 ± 0.41 ROW + manure 72 yes 1.60 yes 2.28 ± 0.58 ROW + compost 72 yes 3.60 yes 2.37 ± 0.40 LEY 101 yes 0.98 yes 2.50 ± 0.31 LEY + manure 109 yes 2.40 yes 2.55 ± 0.38 LEY + compost 109 yes 3.70 yes 2.24 ± 0.63

1 Cropping system and soil amendment treatment. VEG = diversified vegetable rotation; ROW = grain and oilseed rotation; LEY = perennial grass and legume forage.

2 SWET - Soil and Water Eligibility Tool

3 SCI - Soil Condition Index

4 Soil organic carbon, mean ± s.d., n=4

The SWET scores in Table 1 suggest the more-intensively managed vegetable cropping system would degrade soil and water quality, and thus be ineligible for CSP participation. Measurements of SOC suggest this prediction would be false at this site. SWET scores tended to be lower for scenarios without organic matter additions but not enough to change eligibility status based on SWET. Manure and compost addition made a bigger difference in the SCI predictions. Negative SCI scores for the vegetable and row cropped systems without supplemental manure or compost additions predicted a decline in soil organic matter that would have made them CSP ineligible. SOC measured indicate organic matter levels held even where cover crops were the sole source of fertility. In our comparison, both SWET and SCI appeared to overvalue the benefits of supplemental organic matter (particularly compost) additions and the use of perennial pasture and undervalue the benefits of cover crops, particularly in the vegetable cropping system.

Additional Resources- To learn more about EQIP, transitioning to organic agriculture, RC&D's and the additional assistance available from NRCS, contact your local USDA Service Center or visit http://www.nrcs.usda.gov/ (verified 10 March 2010).

- 2008 Farm Bill Side-by-Side [Online]. United States Department of Agriculture—Economic Research Service. Available at http://webarchives.cdlib.org/sw1vh5dg3r/http:/ers.usda.gov/FarmBill/2008/ (verified 10 March 2010).

- Conservation Stewarship Program [Online]. United States Department of Agriculture—Natural Resources Conservation Service. Available at: http://www.nrcs.usda.gov/wps/portal/nrcs/main?ss=16&navid=100120300000000&pnavid=100120000000000&position=SUBNAVIGATION&ttype=main&navtype=SUBNAVIGATION&pname=Conservation%20Stewardship%20Program%20|%20NRCS (verified 10 March 2010).

- For more on the Conservation Benefits of Organic Production go to: http://organicecology.umn.edu/archive/category/education-outreach/page/2/

- For more on Farm Beginnings programs see these websites:

- Minnesota Farm Beginnings, http://www.landstewardshipproject.org/farmbeg.html (verified 10 March 2010)

- Stateline Farm Beginnings, http://www.learngrowconnect.org/what/training/stateline (verified 10 March 2010)

- Central Illinois Farm Beginnings, http://illinoisfarmbeginnings.org/central-illinois-farm-beginnings/ (verified 14 June 2019)

- Dakota Rural Action Farm Beginnings, http://www.dakotarural.org/index.php?option=com_content&view=article&id=... (verified 10 March 2010)

- Lake Superior Farm Beginnings, http://landstewardshipproject.org/morefarmers (verified 10 March 2010)

- Hawthorne Valley Farm Farm Beginnings, http://www.hawthornevalleyfarm.org/education/farmbeginnings.htm (verified 10 March 2010)

- Farm Beginnings Nebraska, http://www.nebsusag.org/farmbeginningsnebraska.htm (verified 10 March 2010)

- Anonymous. 2008. Incentive payments available to new organic farmers. High Plains Journal, Dodge City, KS. 27 Aug. p. 5-B. (Available online at: http://www.hpj.com/archives/2008/sep08/sep1/Incentivepaymentsavailablet.cfm?) (verified 10 March 2010).

- Behar, H. 2008. Organic certification cost share and other 2008 farm bill programs. Organic Broadcaster. Nov/Dec. (Available online at: http://www.mosesorganic.org/attachments/broadcaster/other16.6costshare.html) (verified 10 March 2010).

- Pope, J. 2008. NRCS and RC&Ds help advance organic agriculture across the state. NebNews: the Newsletter of the Nebraska Natural Resources Conservation Service. Summer. p. 3. (Available online at: ftp://ftp-fc.sc.egov.usda.gov/NE/Outgoing/News/nebnews/Summer2008.pdf (verified 10 March 2010).

- Wienhold, B. J., J. L. Pikul, Jr., M. A. Liebig, M. M. Mikha, G. E. Varvel, J. W. Doran, and S. S. Andrews. 2006. Cropping system effects on soil quality in the Great Plains: Synthesis from a regional project. Renewable Agriculture and Food Systems 21: 49–59. (Available online at: http://dx.doi.org/10.1079/RAF2005125) (verified 11 March 2010).

- Zobeck T. M., J. Crownover, M. Dollar, K. F. Bronson, and D. R. Upchurch. 2007. Investigation of Soil Conditioning Index values for southern High Plains agroecosystems. Journal of Soil and Water Conservation 62: 433–442.

This is an eOrganic article and was reviewed for compliance with National Organic Program regulations by members of the eOrganic community. Always check with your organic certification agency before adopting new practices or using new materials. For more information, refer to eOrganic's articles on organic certification.

eOrganic 2842

Managing Manure Fertilizers in Organic Systems

eOrganic author:

Michelle Wander, University of Illinois

This article reviews the basics for manure management in organic systems. Topics covered include National Organic Program regulations, the risk of contaminants in manures, guidelines on how to manage nutrients in manure, and testing manure or compost. Some of the challenges of nutrient supply and test interpretation associated with the repeated use of manures are discussed along with tips and tools you might use to determine manure application rates.

- Introduction, Rules, and Concerns

- Manure Handling: Raw Stacked or Composted

- Managing Nutrients in Manure

- References and Citations

- Additional Resources

Livestock manure is a key fertilizer in organic and sustainable soil management. Manure provides plant nutrients and can be an excellent soil conditioner. Properly managed manure applications recycle nutrients to crops, improve soil quality, and protect water quality. It is most effectively used in combination with crop rotation, cover cropping, green manuring, liming, and the addition of other natural or biologically-friendly fertilizers and amendments.

Use of manure imported from conventional farming operations is allowed by National Organic Program (NOP) standards. There are, however, application restrictions. Manure may only be used in conjunction with other soil-building practices and be stored in a way that prevents contamination of surface or ground water. Many certifiers specify that manure application must not exceed “agronomic application rates”, which means the amount applied must be less than or equal to the requirements of the crop. Manure cannot be applied when the ground is frozen, snow-covered, or saturated.

The NOP regulation (§205.203(c)(1)) specifies that "raw" fresh, aerated, anaerobic, or "sheet composted" manures may only be applied on perennials or crops not for human consumption, or such uncomposted manures must be incorporated at least four months (120 days) before harvest of a crop for human consumption, if the crop contacts the soil or soil particles (especially important for nitrate accumulators, such as spinach). If the crop for human consumption does not contact the soil or soil particles (e.g. sweet corn), raw manure can be incorporated up to 90 days prior to harvest. Biosolids, sewage sludge, and other human wastes are prohibited. Septic wastes are prohibited, as well as anything containing human waste.

Composted plant and animal manures (§205.203(c)(2)) are those that are produced by a process that: (i) established an initial C:N ratio of between 25:1 and 40:1; and (ii) maintained a temperature of 131°F to 170°F for 3 days using an in-vessel or static aerated pile system; or (iii) a temperature of between 131°F and 170°F for 15 days using a windrow composting system, during which period, the materials must be turned a minimum of five times. Alternatively, acceptable composts must meet the November 9, 2006 NOSB Recommendation for Guidance Use of Compost, Vermicompost, Processed Manure and Compost Tea that identifies materials and practices that would be acceptable under 205.203(c)(2). For more information see Making and Using Composts in Organic Systems.

Processed manures are addressed in section §205.203(c)(3). Heat-treated, processed manure may be used as a supplement to a soil-building program, without a specific interval between application and harvest. Producers are expected to comply with all applicable requirements of the NOP regulation with respect to soil quality, including ensuring the soil is enhanced and maintained through proper stewardship.

According to the NOP's July 17, 2007 ruling, “processed manure products must be treated so that all portions of the product, without causing combustion, reach a minimum temperature of either 150°F (66°C) for at least one hour or 165°F (74°C), and are dried to a maximum moisture level of 12%; or an equivalent heating and drying process could be used." To achieve equivalency status, processed manure products can not contain more than 1x10³ (1,000) MPN (Most Probable Number) fecal coliform per gram of processed material sampled and not contain more than 3 MPN Salmonella per 4 gram sample of processed manure.

As always, organic vegetable growers should get label information and check with their certifiers before using purchased compost or processed manure products. See Can I Use This Input On My Organic Farm? for more information.

Some manures are contaminated with hormones, antibiotics, pesticides, disease organisms, heavy metals, and other undesirable substances. Many of the organic compounds, pathogens, protozoa, or viruses can be eliminated through high-temperature aerobic composting. Caution is advised, however, as some disease causing agents, e.g. Salmonella and E. coli bacteria, may survive the composting process. Manure and compost testing is available through commercial labs and is recomended in situations where there is any doubt about the purity of manures. Manure testing is required by the European Union and Canadian standards. The possibility of transmitting human diseases discourages the use of fresh manures and even some composts as pre-plant or sidedress fertilizers on vegetable crops. Apply animal manures at least 90 or 120 days, as applicable, prior to harvest of any crop that could be eaten without cooking.

Best management practices recommended for manure are as follows:

- Avoid manuring after planting a crop to be harvested.

- Incorporation before planting is recommended.

- Do not use dog or cat (fresh or composted) because these species share many parasites with humans.

- Wash all produce from manured fields thoroughly before use.

Cautions or concerns include the following:

- Manures imported from conventional farms can contain residues from hormones or pesticides. (For more information, see Antibiotics and Hormones in Animal Manure Webcast.)

- In rare cases, carryover of persistent herbicides can occur. Most herbicides break down rapidly after application or during normal composting. However, some of those in the pyridine carboxylic acid group such as clopyralid, which is commonly used on grass lawns, break down slowly, even during composting, and are not degraded when ingested by animals because they pass into the urine quickly. Application of manures or composts derived from grass treated with clopyralid is restricted during the “growing season of application” for all farms, not just those that are organic.

- Heavy metals (e.g., As, Cu, and Zn) are fed to livestock and then added to soils in the form of manures. Unlike sludge, metal content does not influence manure application rates to soils but should be considered as metals persist in the soil and will accumulate with repeat application. Concerns over heavy metals, other chemical contaminants, and salinity are most often raised in association with poultry litter. Under federal organic standards, certifiers may require testing of manure or compost if there is reason to suspect high levels of contamination.

- Weed seeds and plant diseases can be effectively controlled by high temperature aerobic composting of manures.

The NOP regulation also requires that manure and other fertility inputs must be managed so that they do not contribute to contamination of crops, soil, or water by excess nutrients, pathogens, heavy metals, or residues of prohibited substances. Whether animals are raised on farm or manures are imported, organic farmers are likely to need to store manure on farm prior to application. Proper manure storage conserves nutrients and protects surface and groundwater. Storing manure can be as elaborate as keeping it under cover in a building, or as simple as covering the manure pile with a tarp. The important point is keeping the pile covered and away from drainage areas and standing water. The storage location should also be convenient to your animals and crop production.

When you are looking for organic forms of nutrients for crop production, manure and manure composts are two of the logical choices. Composting is more than just piling the material and letting it sit. Composting is the active management of manure and bedding to aid the decomposition of organic materials by microorganisms under controlled conditions. Weed and disease problems associated with raw manures can be alleviated with proper composting. Use of composted manures can also reduce P transport to waterbodies (Evanylo et al. 2008).

Organic producers making their own compost must keep records of their composting operation to demonstrate that the compost was produced according to the definition cited above. If the compost is purchased, the grower should ask for documentation from the supplier showing that the compost meets NOP requirements. Keep this documentation, along with purchase receipts, with your other records. If the compost is 100% plant-based, without any animal excrement or by-products, there is no requirement for heating or turning.

Table 1. Comparison of composted and raw manures (from Bary et al., 2000). Compost Manure slow release form of nutrients usually higher nutrient content easier to spread sometimes difficult to spread lower potential to degrade water quality higher potential to degrade water quality less likely to contain weed seeds more likely to contain weed seeds reduced pathogen levels (e.g. salmonella, E. coli) potential for higher pathogen levels higher investment of time or money lower investment of time or money more expensive to purchase less expensive to purchase fewer odors (although poor composting conditions create foul odors) odors sometimes a problem improves soil tilth improves soil tilth Managing Nutrients in Manure

Manure nutrient contents are highly variable and growers must be able to understand and reduce this variability to make the best agronomic and environmental use of these resources. Manure must be carefully managed to prevent over- or under-application and to account for the cumulative environmental effects of application as well as storage. Balancing crop nutritional needs with manures is an ongoing challenge. Finding out about manure composition is critical to its efficient use. Applying too little can lead to inadequate crop growth because of lack of nutrients. Over-application can reduce crop quality and increase the risk of plant diseases. Over-application will also increases the risk of contaminating surface or groundwater.

There are three main sources of variability and uncertainty when using manure:

- Nutrient and moisture content of the manure.

- Material heterogeneity and application variability.

- Availability of nutrients to crops.

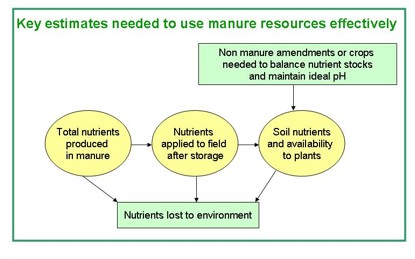

Figure 1. Nutrient flow from manure resources to storage facilities and then to field. Nutrients can be lost from all locations but only those arriving on the field have the chance to feed plants. Figure credit: Michelle Wander, University of Illinois.

Manure composition varies with the species of animal, feed, bedding, and manure storage practices. Table 1 shows typical published values for livestock manure. These values may not accurately represent your situation. Nutrient values can vary by a factor of two or more from the values listed in Table 2. This is why it is important to test materials applied instead of guessing.

Table 2. Typical nutrient content of manure (from Koelsch and Shapiro, 2006). Because of variability between farms, individual manure analysis is preferable to the estimates below. % Dry Matter Ammonium–N Organic–N P2O5 K2O Slurry Manure (lb. of nutrient per 1,000 gallons of manure) Dairy 8 12 13 25 40 Beef 29 5 9 9 13 Swine (finisher, wet-dry feeder) 9 42 17 40 24 Swine (slurry storage, dry feeder) 6 28 11 34 24 Swine (flush building) 2 12 5 13 17 Layer 11 37 20 51 33 Dairy (lagoon sludge)* 10 4 17 20 16 Swine (lagoon sludge) 10 6 16 48 7 Solid Manure (lb. of nutrient per ton of manure) Beef (dirt lot) 67 2 22 23 30 Beef (paved lot)* 29 5 9 9 13 Swine (hood barns) 57 4 13 20 Dairy (scraped earthen lots) 46 3 14 11 16 Broiler (litter from house) 70 15 60 27 33 Layer 40 18 19 55 31 Turkey (grower house litter) 70 15 30 Liquid Effluent from lagoon or holding pond (lbs. of nutrient per acre-inch) Beef (runoff holding pond) 0.25 71 8 47 92 Swine (lagoon) 0.40 91 45 104 189 Dairy (lagoon) 2 317 362 674 1082

Value based upon ASAE, 2005, D384.2; Manure Production and Characteristics with exception of those marked with an "*".

Manure Sampling and TestingCommercial laboratories can measure the nutrients in manure and save you from guessing based on table values. Testing laboratories typically charge from $30 to $60. It is important to use a laboratory that routinely tests animal manure, as they will know the correct type of analysis to use. Extension offices can provide you with publications that list manure testing laboratories in most regions; for example, see the Minnesota Department of Agriculture's listing of manure testing laboratories certified for 2009.

A nutrient analysis is only as good as the sample you take. The best time to sample by far is right before you apply the material because N loss in storage is accounted for. Also, if you use manure repeatedly from the same source, you can develop a running average analysis of that manure (over a 3+ year period). A running average is more likely to be accurate than a single sample taken from a storage pile or lagoon. Samples must be fresh and representative of the manure. Follow these steps:

- Ask the laboratory what type of containers they prefer and make sure the laboratory knows when your sample is coming. Laboratories should receive samples within 48 hours of collection. Plan to collect and send your sample early in the week so the sample does not arrive at the lab on a Friday or a weekend.

- If you have a bucket loader and a large amount of manure, use the loader to mix the manure before sampling.

- Take 10–20 small samples from different parts and depths of the manure pile to form a composite sample. The composite sample should be about 5 gallons. The more heterogeneous your pile, the more samples you should take.

- With a shovel or your hands thoroughly mix the composite sample. You may need to use your hands to ensure complete mixing. Wear rubber gloves when mixing manure samples with your hands.

- Collect about one quart of manure from the composite sample and place in an appropriate container.

- Freeze the sample if you are mailing it. Use rapid delivery to ensure that it arrives at the laboratory within 24–48 hours. You can refrigerate the sample if you are delivering it directly to the lab.

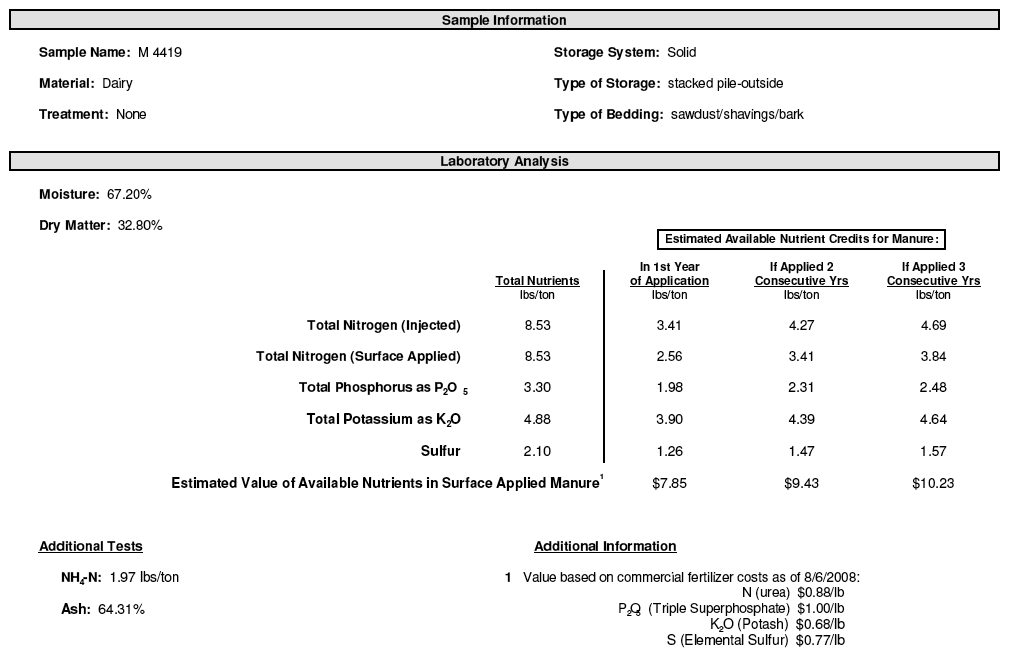

Figure 2. Example of a manure analysis report. Note, the report includes "additional information" about the relative value of nutrients which is subject to change. By convention, available nutrient contents are expressed in terms of reference materials used in fertilizer labels.

Laboratories report results on an as-received or a dry weight basis. As-received results usually are reported in units of lb/ton, while dry weight results usually are reported in percent, ppm, or mg/kg. The “as-received” results, as shown above, are easily used to determining application rates. Dry-weight results can be used to compare analyses over time and from different manure sources.

To convert manure analyses reported on a dry-weight basis (in percent) to an as-received basis (in lb/wet ton), multiply by 20 to convert the dry weight percent to lb/ton; then multiply by the decimal equivalent (23%/100) of the solids content.

Example: For beef manure at 23% solids and 2.4% nitrogen (N) on a dry weight basis:

Step 1. 2.4% x 20 = 48 lb N/ton dry weight

Step 2. 48 lb N/ton dry weight x 0.23 = 11 lb N/ton as-is.

Analyses typically include total nitrogen, ammonium nitrogen (NH4+–N), total phosphorus, total potassium, electrical conductivity, and solids (dry matter). If the manure is old or has been composted you may also want to test for nitrate–N. Total carbon (C) and pH are also useful measurements. Total C can be used to determine the C:N ratio and predict whether or not manure addition is likely to cause nitrogen immobilization. Manure with a C:N ratio greater than 25 is likely to 'tie up' or immobilize nitrogen when you apply it to the soil and stimulate a flush of growth by bacteria and fungi. Bedded manures typically have higher C:N ratios.

Manure Application RatesWhen application rates of manure are based on providing adequate nitrogen for crop growth, added phosphorus and potassium levels will often exceed crop need, so manure should not ve the sole N source in an organic system. Excess levels of soil P can increase the amount of P in runoff, increasing the risk of surface water pollution. Many crops can handle high levels of K, but livestock can be harmed by nutrient imbalances if they consume a diet of forages with high K levels. Annual P-based manure or compost application is the most effective method of application when soil P buildup is a concern (Eghball and Power, 1999). Phosphorus-based application rates improve water quality, but reduce the amount of manure applied per area and so increase the land base needed for manure application. Where P buildup is a concern, legumes should be included in the rotation to provide additional nitrogen.

Typically manure is applied before the most N-demanding crop in the rotation and the amount of N likely to be plant available during the year of application is estimated. Nitrogen availability from manure varies greatly, depending on the type of animal, type and amount of bedding, and age and storage of manure (Table 3). Manure contains nitrogen in the organic and ammonium forms. The organic form releases N slowly, while ammonium–N is immediately available for crop growth.

Table 3. Manure N availability in the first year after application (from Bary et al., 2000). Manure type Total N content (%) % available N Broiler litter 4–6 40–70 Laying hen 4–6 40–70 Sheep 2.5–4 25–50 Rabbit 2.5–3.5 20–40 Beef 2–3 20–40 Dry Stack 1.2–2.5 20–40 Separated Solids 1–2 0–20 Horse 0.8–1.6 0–20

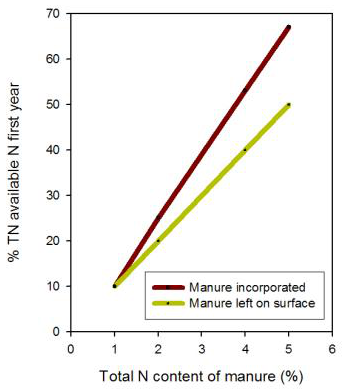

Figure 3. This graph can be used to predict N release based on total N content during the first year after manure application. Figure credit: adapted from Bary et al., 2000.

Solid manures contain most of their nitrogen in the organic form, but poultry manure contains substantial ammonium–N and so should not be surface applied to avoid loss of ammonia gas. Poultry and other manures that contain a large proportion of ammonium–N should be tilled into the soil the same day they are spread. Ammonia loss is greater in warm, dry, and breezy conditions where soil pH is high and is reduced in cool, wet weather. The N availability numbers in Table 2 are approximate ranges for each type of manure. Use the lower part of the ranges if ammonia losses are likely, the manure contains large amounts of bedding, or if the measured N content is lower than typical values. Use the upper range if the manure contains little bedding or if the measured N content is high. Expect first year N tie-up from manures containing less than 1% N. Horse manure or other manures with lots of woody bedding may temporarily tie up nitrogen rather than supply nitrogen for crop growth because the wood is still decaying and bacteria that break down the carbon in the wood consume nitrogen. Composting generally reduces the rate of release of manure N by as much as 50% by converting N into more biologically resistant forms.

"Organic Fertilizer Calculators" like the one linked here are extremely useful tools (Gale et al., 2006). Calculators and manure test information are a far better way to calculate application rates than using tables to estimate manure nutrient content and availability. See Additional Resources for more fertilizer calculators.

Monitoring Soil Nutrient LevelsRepeated applications of manure can increase the pool of slow-release nutrients and so the amount of manure needed to meet crop needs will decline over time. Farmers need to reduce the manure application rate for fields that receive repeated manure applications.

Table 4. Effect of 11 years of annual manure additions on the properties of a heavy clay soil planted to continuous corn silage in Vermont (from Magdoff and Van Es, 2009). Original Level Application Rate (tons/acre/year) 0 10 20 30 Soil organic matter (%) 5.2 4.3 4.8 5.2 5.5 CEC (meq/100g) 17.8 15.8 17 17.8 18.9 pH 6.4 6.0 6.2 6.3 6.4 P (ppm) 4 6.0 7.0 14 17 K (ppm) 129 121 159 191 232 Total Pore Space (%) n.d. 44 45 47 50

Table 4 shows trends where repeat application of manure to a clay soil at three rates has influenced soil properties. Organic matter levels were only maintained where rates equaled 20 tons or more. At these rates P and K levels were in excess. To avoid manure-induced imbalances, continually monitor soil fertility, using appropriate soil tests. Use cover crops and lime or other supplementary fertilizers and amendments to ensure soil balance or restrict application levels if needed.

You can use basic soil tests to evaluate the soil for sufficiency or excess of other nutrients. A basic soil test includes P, K, calcium (Ca), magnesium (Mg), boron (B), pH, EC, and a lime recommendation. If you have consistently low levels of P and K and reduced crop growth, you can probably increase your manure application rates. If you have excessive levels of P and K, you should decrease or eliminate manure applications.

Soil tests can be timed to evaluate different aspects of nutrient supply. Testing the year after manures are applied to assess increased P and K supply is recommended (Heming, 2008). Table 5 shows how test levels rise for several years due to the slow release nature of P contained in many manures.

Table 5. The amount of available phosphorus, expressed as fertilizer equivalent P per tonne or m3, made available in years following manure application increases over time and vaires with the type of manure added (from Heming, 2008). Fertilizer equivalent P per tonne Years after application n Median Mean P Cattle FYM 1 39 0.48 0.62 2 55 0.75 1.21 0.006 3 23 1.1 1.82 0.018 4+ 8 2.2 2.61 0.12 Pig manure 1 11 0.44 0.56 2 11 0.93 0.89 0.04 Poultry manure 1 5 1.21 2.44 2, 3 7 5.23 5.89 0.04 Cattle slurry 1 2 -0.37 -0.37 2, 3 5 1.63 2.92 0.05 Pig slurry 1 3 0.82 0.87 2 6 0.97 1.24 0.46 3 3 1.53 1.13 -0.84

P-values are for the mean FEP being the same as at Ct - 1; italics if P < 0.05. Standard errors for each mean are about 0.5 kg/t for FYM and raw cake, 0.2 for pig manure. The local digested cakes contained about 5 kg total P per tonne and raw cake 2.5 kg total P per tonne.

Late season sampling (0–12 inches or more) can be used to determine whether there is surplus nitrate-N remaining in the soil in the fall. If you apply too much manure, unused nitrate N will accumulate. When the fall and winter rains come, the nitrate will leach from the soil and become a potential contaminant in groundwater or surface water. Excess N can also harm some crops, delaying fruiting and increasing the risk of disease damage, freeze damage, and wind damage. Take a "report card" sample as you would any other soil sample, collecting soil cores at multiple spots in the field, and combining the cores together into a composite sample. If late season nitrate–N results are greater than 15–20 mg/kg, you are supplying more N than your crop needs and should reduce or avoid manure application. Report-card nitrate-N levels greater than 30 mg/kg are excessive.

Nutrient requirements for specific crops can be found in Cooperative Extension production guides or from soil test recommendations. Crop performance can be used to help fine tune application rates.

References and Citations- Agricultural Marketing Service—National Organic Program [Online]. United States Department of Agriculture. Available at: http://www.ams.usda.gov/nop/ (verified 10 March 2010).

- Bary, A., C. Cogger, and D. Sullivan. 2000. Fertilizing with manure. PNW0533. Pacific Northwest Extension Publications, Washington State University, Pullman. (Available online at: https://pubs.wsu.edu/ItemDetail.aspx?ProductID=14941&SeriesCode=&Categor...) (verified 10 March 2010).

- Evanylo, G., C. Sherony, J. Spargo, D. Starner, M. Brosius, and K. Haering. 2008. Soil and water environmental effects of fertilizer-, manure-, and compost-based fertility practices in an organic vegetable cropping system. Agriculture, Ecosystems & Environment 127: 50–58. doi:10.1016/j.agee.2008.02.014

- Gale, E. S., D. M. Sullivan, C. G. Cogger, A. I. Bary, D. D. Hemphill, and E. A. Myhre. 2006. Estimating plant-available nitrogen release from manures, composts, and specialty products. Journal of Environmental Quality. 35: 2321–2332.

- Heming, S. D. 2008. The fertilizer equivalent of phosphorus and potassium in organic manures applied to arable soils. Soil Use and Management 24: 318–322. doi:10.2134/jeq2006.0062

- Koelsch, R., and C. Shapiro. 2006. Determining crop available nutrients from manure. NebGuide G1335. University of Nebraska Extension, Lincoln. (Available online at: http://efotg.sc.egov.usda.gov/references/public/NE/G1335_Determining_Cro...) (verified 12 March 2014).

- Kuepper, G., 2003. Manures for organic crop production [Online]. ATTRA Publication #IP127. National Sustainable Agriculture Information Service. Available at: https://attra.ncat.org/product/manures-for-organic-crop-production/ (verified 14 June 2019).

- Magdoff, F., and H. Van Es. 2009. Building soils for better crops. 3rd ed. Sustainable Agriculture Network Handbook Series Book 10. National Agricultural Laboratory, Beltsville, MD. (Available online at: http://www.sare.org/publications/bsbc/bsbc.pdf) (verified 10 March 2010).

- United States Department of Agriculture. 2000. National organic program: Final rule. Codified at 7 C.F.R., part 205. (Available online at: http://www.ecfr.gov/cgi-bin/text-idx?SID=a6a0935ddf00e166695f4c2138bd58d...) (verified 10 March 2010).

- Andrews, N. and J. Foster. 2007. Organic Fertilizer Calculator: A tool for comparing the cost, nutrient value, and nitrogen availability of organic materials. EM 8936-E. Oregon State University Extension Service, Corvallis. (Available online at: http://smallfarms.oregonstate.edu/organic-fertilizer-calculator) (verified 10 March 2010).

- Certified Manure Testing Laboratories [Online]. Minnesota Department of Agriculture. Available at: http://www2.mda.state.mn.us/webapp/lis/manurelabs.jsp (verified 10 March 2010).

- Manure Nutrient Availability Calculator [Online]. Manure Management Planner. Purdue Research Foundation, West Lafayette, IN. Available at: http://www.agry.purdue.edu/mmp/webcalc/nutAvail.asp (verified 10 March 2010).

- Manure Plant Available Nitrogen (PAN) Calculation [Online]. Resources for Nutrient Management Planners. University of Missouri Extension, Columbia. Available at: http://nmplanner.missouri.edu/tools/pan_calculator.asp (verified 10 March 2010).

- Seal of Testing Assurance [Online]. U.S. Composting Council. Available at: http://www.compostingcouncil.org/programs/sta/ (verified 10 March 2010).

- Sullivan, D. M. 2008. Estimating plant-available nitrogen from manure [Online]. EM 8954-E. Oregon State University Extension, Corvallis. Available at: http://ir.library.oregonstate.edu/xmlui/bitstream/handle/1957/20528/em89... (verified 12 March 2014).

This is an eOrganic article and was reviewed for compliance with National Organic Program regulations by members of the eOrganic community. Always check with your organic certification agency before adopting new practices or using new materials. For more information, refer to eOrganic's articles on organic certification.

eOrganic 3132

Organic Farming and Soil Health in the Western U.S. Webinar Series

The Organic Farming Research Foundation and eOrganic presented eight free webinar trainings on organic farming and soil health in the Western U.S. The webinars target agricultural professionals including Extension personnel, other agency personnel, and agricultural consultants in an effort to increase expertise in organic practices that promote soil health. This series is a perfect complement to the farmer guides OFRF has produced on organic soil health practices, available here. The goal of the trainings is to address the need for region-specific resources and knowledgeable Extension services related to organic soil health, biology, nutrient cycling, and more! Recordings, slides and additional presentation notes are available below.

About the PresenterDr. Mark Schonbeck of the Organic Farming Research Foundation will be joined by experts in the Western Region to review the most recent soil health research and practices relevant to the Western Region. The webinars will provide an overview of the topic, best practices for the Western Region, in-depth analysis of the latest research, and an extensive question and answer session after each presentation.

October 24, 2018: Ecological Nutrient Management for Organic Production in the Western RegionThis webinar will explore the role of the soil food web in nutrient cycling and provisioning, and practical strategies for optimizing the availability of limiting nutrients, such as nitrogen, for soil health, organic crop production, and water quality. We will summarize recent research on nitrogen management for organic vegetable and strawberry production in maritime, Mediterranean, and semiarid climates.

Slide handout, Presentation Notes, Recording link: https://www.youtube.com/watch?v=hkXBexLSefk

November 21, 2018: Ecological Weed Management for the Western RegionIn this webinar we will focus on integrated organic weed management strategies that help desired vegetation outcompete weeds, build soil health, and reduce the need for soil disturbance. In addition, we will summarize outcomes of recent research into organic management of field bindweed and other major weeds of Western Region cropland and rangeland.

Slice Handout, Presentation Notes

January 23, 2019: Practical Conservation Tillage for Western Region Organic Cropping SystemsThis webinar will discuss practical approaches to reducing the adverse impacts of tillage and cultivation on soil life and soil health. We will also cover recent research into newer tillage tools and minimum-till strategies for Western Region organic vegetable, fruit, and field crop production.

Slide handout, Presentation Notes, Recording at https://www.youtube.com/watch?v=KFuO_fFo8ls

February 27, 2019: Selecting and Managing Cover Crops for Organic Crop Rotations in the Western RegionCo-presenter: Eric Brennan, USDA ARS, Salinas, CA.

This webinar will discuss best cover crops, mixes, and management methods for optimum soil health and organic cash crop production in the Western Region. We will explore in greater depth the special challenges that farmers face in adding cover crops to dryland cereal grain rotations and other moisture-limited cropping systems.

Eric is a research horticulturist and lead scientist in organic production at the USDA Agricultural Research Service in Salinas, CA where he has worked since 2001. Eric’s research focuses on vegetable and strawberry production with emphasis on cover crops, weed and soil fertility management, and biological control of insect pests. Eric is passionate about long-term research and effective communication of practical research results to farmers and others.

Slide handout, Presentation notes, Recording at https://www.youtube.com/watch?v=wfaBAqUMuo8

March 27, 2019: Breeding New Cultivars for Soil-enhancing Organic Cropping Systems in the Western Regionwith Jared Zystro of the Organic Seed Alliance and Dawn Thilmany of Colorado State University.

This webinar will summarize plant breeding endeavors toward improved vegetable, specialty grain, and other crop cultivars for organic producers in the Western Region, and practical resources to help organic producers obtain the best available seed varieties for their needs. We will also explore emerging opportunities to develop new cultivars for nutrient and moisture use efficiency, competitiveness toward weeds, and enhanced interactions with beneficial soil biota.

Slide handout, Presentation notes, Recording at https://www.youtube.com/watch?v=auTHGHRUbKk

April 17, 2019: Preparing for Drought: The Role of Soil Health in Water Management in Organic ProductionWith climate change exacerbating water scarcity issues throughout the Western U.S., organic producers urgently need practical information on best irrigation and soil moisture management. This webinar will explore the role of best organic soil health management in water conservation and water quality, with emphasis on practical research outcomes for the Western Region.

Slide handout, Presentation notes, Recording at https://www.youtube.com/watch?v=HucXx2E-99Q

May 29, 2019: Meeting Weather Challenges in the Western U.S.: Organic Practices to Mitigate and Prepare for Climate ChangeSlide handout, Presentation notes, Recording at https://www.youtube.com/watch?v=xxXeLJtWFzs

Co-presenter: Maegen Simmonds

This webinar will explore the capacity of sustainable organic systems to sequester soil carbon, minimize agricultural greenhouse gas emissions, and help organic cropping and livestock operations withstand the impacts of climate disruptions already underway. Our presentation will include a summary of recent research findings and practical implications for the Western Region.

Maegen Simmonds is a soil and ecosystem biogeochemist, modeler, and data scientist who works to ensure the long-term sustainability of ecosystems by informing best management practices, decision-making, and policy. Her research focuses on terrestrial ecosystem processes, including land-atmosphere exchange of greenhouse gases (CO2, CH4, N2O). Predicting the interactive effects of climate, wildfire, soil and plant properties, and land management have been central themes in her work.

June 12, 2019: Soil Biology for the Western Region: Organic Practices to Recruit and Nurture Beneficial Biota in the SoilThis webinar will examine the roles of the soil food web and key components thereof in promoting soil health and fertility and sustainable organic crop production. Recent research conducted in organically managed soils in the Western Region will provide the basis for practical guidelines for best soil food web management in organic farming and ranching systems.

Slide handout, Presentation notes.

Funding for this webinar series is being provided by Western SARE.

This is an eOrganic article and was reviewed for compliance with National Organic Program regulations by members of the eOrganic community. Always check with your organic certification agency before adopting new practices or using new materials. For more information, refer to eOrganic's articles on organic certification.

eOrganic 27448

Composting to Reduce Weed Seeds and Plant Pathogens

eOrganic author:

Ed Zaborski, University of Illinois at Urbana-Champaign

A key feature of organic farming systems is the utilization of organic residues as soil mulches and amendments in an integrated system to maintain and improve soil quality. Organic residues used for these purposes may be produced on the farm, or they may be imported from off-farm sources. Often, fresh organic residues produced in place are used in these practices, such as when cover crops are plowed down as a green manure to build soil organic matter and improve soil fertility, or rolled as a mulch in organic no-till systems to suppress weeds, reduce soil erosion, and conserve soil moisture. Organic residues may also be processed before being used to attain desirable qualities, such as when animal manures are composted to reduce volume and improve stability. Regardless of the circumstances, organic residues that are handled incorrectly can introduce otherwise avoidable problems to the farming system. For example, raw cattle manure may contain viable weed seeds and may spread an otherwise isolated weed infestation more broadly across the farm or, if the manure is imported from outside the farm, introduce a weed problem that previously didn't exist. Similarly, plant residues may be infected with pathogens that can infest subsequent crops. This article provides a brief description of the composting process, discusses the use of composting to reduce weed seeds and plant pathogens, and identifies issues that can lead to the failure of composting to reduce weed seeds and plant pathogens.

What is composting?

For the purposes of organic certification, the National Organic Program rule (United States Department of Agriculture [USDA], 2000) defines compost as:

"The product of a managed process through which microorganisms break down plant and animal materials into more available forms suitable for application to the soil. Compost must be produced through a process that combines plant and animal materials with an initial C:N ratio of between 25:1 and 40:1. Producers using an in-vessel or static aerated pile system must maintain the composting materials at a temperature between 131 °F and 170 °F for 3 days. Producers using a windrow system must maintain the composting materials at a temperature between 131 °F and 170 °F for 15 days, during which time, the materials must be turned a minimum of five times."

–7 C.F.R. § 205.2 (2000)

Composting is the controlled management of the normal biological process of aerobic (in the presence of oxygen) decomposition of organic residues by microorganisms such as bacteria, fungi, and actinomycetes. This process is optimized when the various organic residues are mixed to provide certain conditions:

- a balance of energy (carbon, C) and nutrients (primarily nitrogen, N), with an initial C:N ratio of between 25:1 and 40:1

- sufficient—but not excessive—moisture (typically 40–60% by weight)

- sufficient oxygen to support an aerobic environment (typically 5% or more)

- a pH in the range of 6–8

Under these conditions, populations of microorganisms will thrive and organic residues will be decomposed, consuming oxygen and releasing intermediate breakdown products, carbon dioxide, and heat. As the temperature of the pile rises, the community of microorganisms will go through a succession, culminating in thermophilic (heat-loving) organisms at temperatures above 113 °F (45 °C). If the mass of the compost pile is large enough to be self-insulating, temperatures within the pile during this active phase of composting may reach 131–170 °F (~55–70 °C) within 1–3 days. To maintain biological activity and to bring the active phase to completion, temperatures should be monitored and compost moisture and aeration should be maintained. After the most readily decomposable organic matter in the compost is consumed, biological activity will decrease in intensity, and temperatures and oxygen consumption will decline. The compost then enters the curing phase, during which decomposition proceeds more slowly and organic matter is converted to stable humic substances—the finished or mature compost.

See the related article, Making and Using Compost in Organic Agriculture, for more information about composting.

How does composting reduce weed seeds?Several factors contribute to weed seed mortality during composting. In compost systems assembled and managed in accordance with requirements for organic certification, the most important factors are the interaction between weed species, temperature, time, and moisture (Eggley, 1990; Shiralipour and Mcconnell, 1991; Eghball and Lesoing, 2000; Larney and Blackshaw, 2003; Dahlquist et al., 2007). In general, the higher the temperature to which weed seeds are exposed during the active phase of composting, the higher the weed seed mortality. Similarly, the longer the duration of high-temperature exposure, the higher the weed seed mortality. Thus, Dahlquist et al. (2007) estimated that three of the six weed species they examined under controlled laboratory conditions were unaffected by temperatures of 108 °F, but 90% of the seeds of all six species were killed after less than three hours at 140 °F (Table 1). Furthermore, all six species suffered 100% mortality after less than an hour at 158 °F. Similarly, in Texas, Weise et al. (1998) found that, in composting manure at 35% moisture, barnyardgrass, pigweeds, and kochia seeds were killed after three days at 120 °F; Johnsongrass seed was killed with three or more days of exposure at 160 °F; but field bindweed seeds were killed only after seven days at 180 °F.

Table 1. Estimated number of hours required to kill 90% of seeds (after Dahlquist et al., 2007). Temperature (°F) 140 122 115 108 time required to kill 90% of seeds (hours) Annual sowthistle <1.0 2.1 13.3 46.5 Barnyardgrass <1.0 5.4 12.6 unaffected London rocket <1.0 4.0 21.4 83.1 Common purslane 1.3 18.8 unaffected unaffected Black nightshade 2.9 62.0 196.6 340.6 Tumble pigweed 1.1 107.0 268.5 unaffectedSusceptibility of weed seeds to thermal mortality, however, is influenced by the moisture content of the compost; weed seeds in a dry environment are able to survive higher temperatures for longer times than seeds in a moist environment. Some (Egley, 1990; Thompson et al., 1997) have suggested that thermal mortality may be greatest for fully imbibed seeds—seeds that have absorbed water and split their seed coat in the process of germination. In Nebraska, Eghball and Lesoing (2000) showed that adding water to beef manure compost greatly enhanced weed seed destruction; moist compost was faster and more effective at killing cocklebur, morningglory, pigweed, sunflower, velvetleaf, foxtail, smooth brome, and shattercane than dry compost, in part due to higher compost temperatures.